Insulating glass is a new type of building material with two pieces (or three pieces) of glass, which is bonded with an aluminum alloy frame by using high-strength and high-air-tight composite adhesive. It has good heat insulation, sound insulation and beautiful appearance. . Insulating glass units usually use two-way sealant, that is, polyisobutylene rubber is used as the first seal, and organic silica gel, polysulfide rubber or polyurethane glue is used as the second seal. In this paper, two-component polyurethane sealant for insulating glass was prepared by using hydroxyl-terminated liquid polybutadiene and crude MDI as main raw materials, and the filler, plasticizer, chain extender, adhesion promoter and catalyst pair were studied. The effect of the glue properties.

Experimental materials: hydroxyl-terminated liquid polybutadiene, Poly bd® R45V, Crayville (Guangzhou) Chemical Co., Ltd.; crude MDI, WANAATE® PM-200, Wanhua Chemical Group Co., Ltd.; nano calcium carbonate, WINNOFIL® SPM, SOLVAY; heavy calcium carbonate, OMY-2, Omega (Shanghai) Investment Co., Ltd.; plasticizer, DIDP, ExxonMobil Chemical; chain extender, 1,4-butanediol (1,4- BDO), Shanghai Tishhi Ai; adhesion promoter, Silquest® A-187, Momentive Advanced Materials (China) Co., Ltd.; catalyst, ZJPC-0225, homemade.

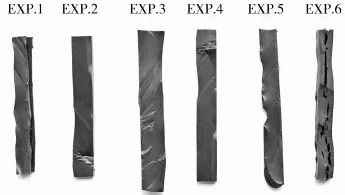

(1) The effect of NCO/OH ratio on the performance of insulating glass sealant: Generally, the closer the ratio of NCO/OH is to 1, the closer the sealant is to the gel point, the faster the reaction cross-linking speed, but too fast. The crosslinking speed affects the operability of the polyurethane sealant. Therefore, the selection of the appropriate NCO/OH ratio is crucial for the two-component polyurethane insulating glass glue. The performance of the two-component polyurethane insulating glass sealant was investigated by comparing different NCO/OH ratios. The results are shown in Table 1 and Figure 1 shows.

Table 1 Effect of NCO/OH ratio on properties of insulating glass sealant

Figure 1 After the cured strip is cut

It can be seen from the results in Table 1 that when the NCO/OH ratio is below 1.19, the pot life of the two-component polyurethane rubber sample is too short; when the NCO/OH ratio is above 1.34, the operable time of the two-component polyurethane rubber sample In order to meet the construction requirements, when the NCO/OH ratio reaches 1.80, a certain bubble appears in the cured strip as shown in Figure 1. Therefore, the ratio of NCO/OH is suitably from 1.34 to 1.64. Considering the ratio error of the actual construction process of the A and B components, it is more appropriate to choose the NCO/OH ratio of about 1.5.

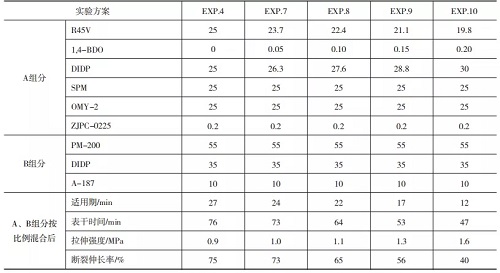

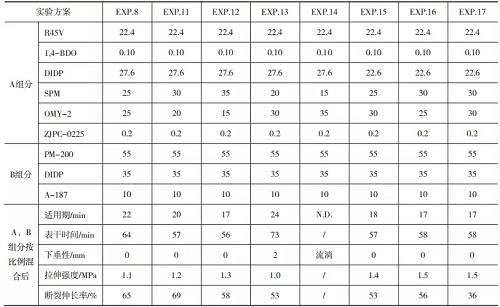

(2) Effect of chain extender content on mechanical properties of insulating glass sealant: In the formulation of polyurethane adhesive, some active hydrogen-containing compounds are often reacted with isocyanate-terminated prepolymer to prolong the molecular chain diffusion and improve The initial strength of the polyurethane glue. The effect of 1,4-BDO on the properties of two-component polyurethane insulating glass glue was investigated. The results are shown in Table 2.

Table 2 Effect of chain extender content on properties of insulating glass sealant

It can be seen from Table 2 that the addition of a small amount of 1,4-BDO can reduce the amount of R45V used, increase the tensile strength of the sealant, and reduce the dry time of the sealant, but at the same time reduce the operable time and breakage of the sealant. Elongation. Therefore, the ratio of the more suitable 1,4-BDO chain extender herein is 0.10%.

(3) The ratio of nano-calcium carbonate and heavy calcium carbonate to the performance of the sealant: Nano-calcium carbonate is mainly used to improve the thixotropy, strength and toughness of the product, but the thickening is obvious, so it can only be partially added in the product; Heavy calcium carbonate is mainly used to reinforce and act as a filler, reducing the cost of the formulation, so choosing the appropriate ratio of nano-calcium carbonate and heavy calcium carbonate plays a key role in the overall performance of the sealant. Table 3 lists the effect of different ratios of nano-calcium carbonate and heavy calcium carbonate on the properties of two-component polyurethane insulating glass sealants. It can be seen from the results in Table 3 that when the proportion of nano-CaCO3 is 20% and the proportion of heavy calcium carbonate is 30%, the sealant exhibits poor thixotropic properties, and at the same time, high filler content may cause rubber resistance. The aging performance is not good, so the more suitable nano calcium carbonate ratio in this paper is 25%, and the proportion of heavy calcium carbonate is 25%.

Table 3 Effect of nanometer calcium carbonate and heavy calcium carbonate on the performance of sealant

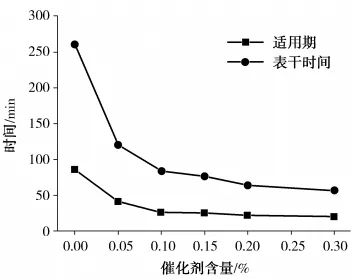

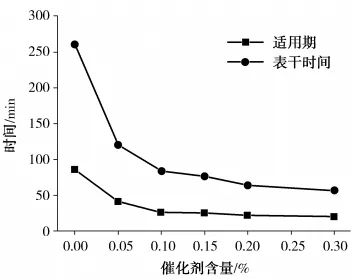

(4) Effect of catalyst content on sealant pot life and surface drying time: The results are shown in Figure 2. It can be seen from Fig. 2 that the two-component polyurethane sealant has a long application period (86 min) without adding a catalyst, but the dry time of the same glue is also long, reaching about 260 min. Therefore, it will greatly affect the construction efficiency of the site. From the results of this study, the more suitable catalyst ZJPC-0225 is used in an amount of 0.1% to 0.2%. Considering the error range of the formulation during actual construction, the better catalyst content in this paper is 0.15%.

Figure 2 Effect of catalyst content on the pot life and dry time of sealant

(5) Effect of the amount of adhesion promoter on the adhesive properties of the sealant: The influence of the content of the adhesion promoter on the adhesive properties of the sealant was studied. The results are shown in Fig. 3. As can be seen from Figure 3, the addition of the adhesion promoter greatly improves the interfacial adhesion of the two-component polyurethane insulating glass sealant. When the A-187 content reaches 10%, the two-component polyurethane sealant sample can achieve a better bonding effect. Further increase in the content of A-187 does not reduce the interfacial adhesion of the two-component polyurethane sealant sample, but at this time, the sample is sticky, and therefore, the content of the better adhesion promoter in this experiment is 10%.

Figure 3 Effect of the amount of adhesion promoter on the bonding properties of the sealant

Through a series of experiments, the effects of fillers, plasticizers, chain extenders, adhesion promoters and catalysts on the properties of sealants were studied by using hydroxyl-terminated liquid polybutadiene and crude MDI as main raw materials. The study found that when the ratio of NCO/OH in the two-component polyurethane sealant is 1.5, the content of the terminal hydroxyl liquid polybutadiene R45V in the A component is 22.4%, and the chain extender 1,4-BDO content is 0.1%, plasticizing. The content of DIDP is 27.6%, the content of SPM in nanometer calcium carbonate is 25%, the content of heavy calcium carbonate OMY-2 is 25%, the content of catalyst ZJPC-0225 is 0.15%, and the content of crude MDI PM-200 in component B is 55%. When the plasticizer DIDP content is 35% and the adhesion promoter A-187 content is 10%, the prepared two-component polyurethane sealant has better comprehensive performance and can meet the requirements of the insulating glass two-way sealant.